Continuous filament of yarn structure

In a steel or in a rope

structure, one strand or component remains in the centre, and all other

components have a specific and constant radius of spirality (Helix), remaining

in an annular envelope about the center or cable axis. In examining a segment

of the cable, one would find the longest components at the surface and the

shortest component in the centre. This is possible because each component is

individually controlled by tension or rate of feeding during formation of the

cable or rope.

In a steel or in a rope

structure, one strand or component remains in the centre, and all other

components have a specific and constant radius of spirality (Helix), remaining

in an annular envelope about the center or cable axis. In examining a segment

of the cable, one would find the longest components at the surface and the

shortest component in the centre. This is possible because each component is

individually controlled by tension or rate of feeding during formation of the

cable or rope.

During the twisting of multi continuous filaments, however, there exists no control of the tension or rate of feeding of the individual filaments resulting a self-equalization tension phenomenon wherein the individual filaments exchange positions radially among the various annular zones in the assemblage. Those filaments going to the outer layers of the yarn develop more tension and, being tight, force themselves to the center of the yarn to relieve the tension. The filaments in the core of the yarn is under less tension are pushed to the yarn surface. This means that every filament is entangled periodically at both surface and core of the yarn.

In a steel or in a rope

structure, one strand or component remains in the centre, and all other

components have a specific and constant radius of spirality (Helix), remaining

in an annular envelope about the center or cable axis. In examining a segment

of the cable, one would find the longest components at the surface and the

shortest component in the centre. This is possible because each component is

individually controlled by tension or rate of feeding during formation of the

cable or rope.

In a steel or in a rope

structure, one strand or component remains in the centre, and all other

components have a specific and constant radius of spirality (Helix), remaining

in an annular envelope about the center or cable axis. In examining a segment

of the cable, one would find the longest components at the surface and the

shortest component in the centre. This is possible because each component is

individually controlled by tension or rate of feeding during formation of the

cable or rope.During the twisting of multi continuous filaments, however, there exists no control of the tension or rate of feeding of the individual filaments resulting a self-equalization tension phenomenon wherein the individual filaments exchange positions radially among the various annular zones in the assemblage. Those filaments going to the outer layers of the yarn develop more tension and, being tight, force themselves to the center of the yarn to relieve the tension. The filaments in the core of the yarn is under less tension are pushed to the yarn surface. This means that every filament is entangled periodically at both surface and core of the yarn.

Yarns with minimal twist or

entanglement will have a very long fiber segment length between points of

entanglement, the filaments are free to spread, and there is no definite or

stable yarn cross-sectional shape or diameter.

Yarns with more twist, the degree

of linearity of filament segment lengths

in the yarn decreases slightly leading to reduced strength. This reduction in

yarn strength occurs because the more linear filaments are strained immediately

on loading, whereas the less linear filaments tend to straightened and then

strained. However, greater twist also reduces the average length of the

filament segments between points of entanglement and the tendency for filaments

to spread out and snag .With sufficient more twist, the cross section of a

filament yarn can be given more support so that, under a compressive or bending

deformation, an elliptical shape occurs rather than a total collapse or

flattening out of the filament assemblage. Increased twist in filament yarn

also leads to greater bending stiffness in the yarn structure primarily because

of greater entanglement and friction among the filaments.

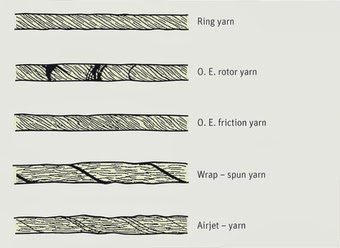

STAPLE YARN STRUCTURE

The structure of staple (Spun)

yarns is an order of magnitude more complex than the structure of continuous

filaments. Although a high-quality staple yarn may appear to be as uniform as a

filament yarn, closer examination would indicate a random grouping of the fiber

and a variation in twist and in linear density, resulting in thick and thin

spots along the length of yarn. Also noticeable would be a concentration of

fiber forming a core

in the centre of the yarn and an

outer fringe of fiber known as fuzz zone caused by protruding fiber ends. An

untwisting of the spun yarn structure would indicate a more thorough and

frequent tying-in of the surface and core layers than found in filament yarns.

Examination of low-quality staple yarn would show many localized fiber

entanglements or hard spots known as neps that are contained in the structure.

A tremendous variation in the

quality of staple yarns and uniformity of yarn structure is possible because of

the manner in which the fibers are processed previously. Staple fibers are

handled as a mass rather than as individuals and therefore tend to behave and

to process in groups and sub-groups. The fibers tend to participate to a much

greater extent in their own processing than in the case of filament processing.

Each staple has two free ends that may protrude, contributing to fuzz or may

bend, hook, buckle, or roll on themselves or in conjunction with other fibers.

Intermediate staple fiber assemblages (sliver and roving) contain a slight

internal entanglement caused mainly by the condensation of fiber web into

linear assemblages. Also some twist is normally incorporated into the roving

structures. In the final stage of staple yarn formation, a rather greater

amount of twist is superimposed onto the existing looser entanglement.

In blends of fibers with

substantially different processing characteristics, an abnormal fiber migration

may occur that is known as preferential radial migration or coring; one

component of the blend is found primarily in the core and the other component

mostly near the surface.

Comments

Post a Comment